In modern industrial screening production lines, efficient, precise, and stable screening equipment is crucial for ensuring product quality and production efficiency. Circular gyratory screens, as an advanced screening machine that simulates the principle of manual screening, have become an indispensable core component in production lines across many industries due to their unique technological advantages.

Seamless Integration, Optimized Production Line Flow

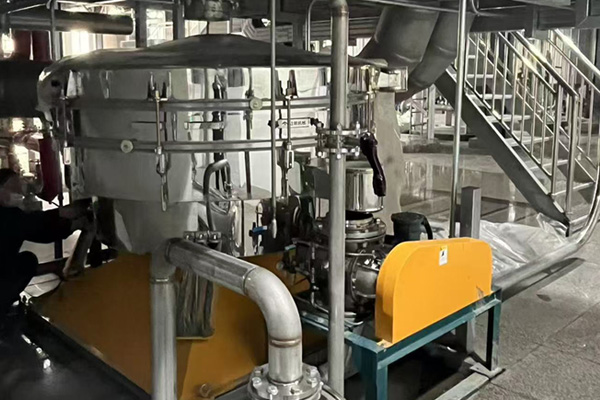

The compact design of the circular tumbler screen facilitates integration into existing production lines. It is typically installed after crushing, mixing, or granulation processes and before packaging or further processing, acting as a "gatekeeper" for fine grading and quality control.

-Upstream Connection: It can easily receive materials from bucket elevators, screw conveyors, or vibrating feeders. Its inlet design effectively reduces material impact and spillage.

-Downstream Diversion: Through a multi-layer screen configuration, materials can be precisely divided into 2-6 different particle size components in a single pass. Each outlet can be connected to different conveyor belts, silos, or packaging machines, achieving automated diversion operations and greatly simplifying the process flow.

Unique Principle, Addressing Complex Screening Challenges

The core of the circular tumbler screen lies in its three-dimensional gyratory motion. Under the influence of inertial force, the screen body generates a three-dimensional elliptical motion trajectory that is horizontal, vertical, and inclined. This motion brings multiple advantages:

1. High-precision screening: The gentle gyratory motion allows the material to be fully dispersed on the screen surface and move gradually in a spiral pattern. Fine particles have ample opportunity to pass through the mesh, significantly improving screening accuracy and throughput.

2. Preservation of particle shape: Compared to violent linear or elliptical vibrations, the gyratory motion has less impact on the material, effectively preventing breakage of fragile, crystalline, or agglomerated materials, maintaining their original shape.

3. Anti-clogging and self-cleaning: During the motion, the cleaning bouncing balls installed under the screen continuously bounce and impact the screen, effectively preventing fine particles from clogging the mesh and ensuring continuous and efficient screening.

Automation and Intelligent Control Integration

In modern production lines, circular tumbler screens are often linked with automation systems:

- Interlocking control: Interlocked with upstream grinding mills and downstream conveying systems to achieve synchronized start and stop, optimizing energy efficiency. - Real-time monitoring: Equipped with an observation window, screen blockage alarm, and even connectable to vibration sensors for status monitoring, facilitating predictive maintenance.

- Quick screen change: Utilizing a mother-daughter screen frame or quick-clamping device, screens can be quickly changed according to product specifications, reducing downtime and adapting to the flexible production needs of multiple varieties and small batches.

Integrating the circular tumbler screen into a screening production line not only automates and continues the process but also significantly improves the quality of the final product and the overall efficiency of the production line with its high-precision, high-output, and low-breakage screening effect. It is a key step in achieving efficient material classification in modern precision manufacturing processes.

The circular tumbler screen, a core product of Mirant Xinxiang Machinery in the field of intelligent screening, has gained widespread customer recognition for its excellent screening and grading capabilities, providing solutions for screening production lines across numerous industries. We adhere to the principles of "quality assurance, reputation first, quality-oriented, and win-win cooperation," focusing on customer needs to ensure the manufacture of high-quality products that are stable in performance, of superior quality, aesthetically pleasing, and easy to operate.

Clearly separated particles, intelligent screening – Mirant Xinxiang Machinery Equipment Co., Ltd.