As a core component of screening equipment, the lifespan and condition of the screen directly determine screening efficiency, product quality, and production costs. Premature screen breakage (abnormal wear and tear) and severe clogging are among the most common problems in production lines, requiring systematic optimization from multiple dimensions, including selection, installation, process, and maintenance.

Screen Problems and Their Direct Impacts

- Abnormally Shortened Lifespan: The screen experiences localized or overall abnormal wear and tear, requiring replacements far more frequently than designed, increasing spare parts costs and downtime.

- Severe Performance Degradation: Clogged screen openings lead to a sharp reduction in effective screening area, decreased processing capacity (output), loss of particle size classification accuracy, and an increased product defect rate.

- Deteriorating Operating Conditions: Often accompanied by poor material discharge from the screen and uneven material distribution on the screen surface (localized accumulation), further exacerbating equipment load and screen damage.

Root Cause Analysis

Problems usually arise from a combination of factors, primarily categorized into the following four aspects:

1. Incorrect Selection of Core Components

- Material Mismatch: For example, using ordinary 304 stainless steel mesh to process highly corrosive materials, or failing to select a material with higher hardness for highly abrasive materials.

- Inappropriate Structure: The mesh wire diameter, aperture, and weaving method (e.g., plain weave, twill weave) are incompatible with the characteristics of the material (e.g., flaky or fibrous materials are prone to jamming), indicating a lack of targeted design.

2. Poor Installation and Mechanical Condition

- Insufficient Tension: This is the primary cause of screen fatigue failure. A loose screen generates severe secondary vibrations and impacts during operation, creating additional friction with the support beams and materials, accelerating breakage.

- Impact at the Feeding Point: Improperly designed feed inlet leads to vertical and concentrated impacts of material onto the same area of the screen, creating "wounds" and causing premature localized damage.

3. Process Conditions and Material Changes

- Sudden Changes in Material Properties: Increased feed moisture, oil content, or higher levels of viscous components are direct causes of screen adhesion and clogging. Severe static electricity in the material can also exacerbate the adsorption and clogging of fine powders.

- Screen Cleaning System Failure: Malfunction, wear, or improper parameter settings of the supporting screen cleaning devices (such as bouncing balls, ultrasonic generators, and scrapers) can lead to a loss of the ability to continuously clean the screen openings.

4. Lack of Preventive Maintenance

The absence of a system for regularly checking screen tension, cleaning device status, and screen surface condition allows small problems to accumulate into major malfunctions.

Systematic Solutions and Prevention Strategies

Solving screen problems requires a systematic engineering approach of "prevention first, combined with control."

Phase One: Precise Selection and Professional Installation (The Fundamental Solution)

- Scientific Selection:

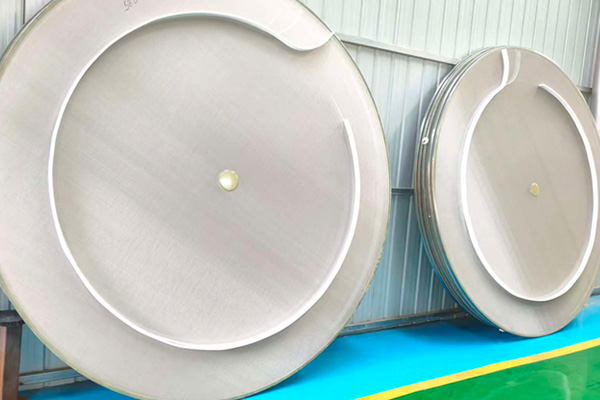

Wear-resistant and Corrosion-resistant: For highly abrasive materials, select 65Mn spring steel, high-carbon steel, or polyurethane screens; for corrosive environments, select 316L stainless steel or plastic materials.

Anti-clogging design: For materials prone to clogging, square-hole, anti-clogging woven screens or polymer material screen plates can be selected. For static electricity-laden materials, anti-static materials or metal wires can be added.

-Proper installation:

Use professional tools: Always use dedicated tensioning tools (such as tension gauges or hydraulic tensioners) for installation to ensure uniform force on the screen and consistent tension. This is the most critical step in ensuring screen life.

Add a buffer distributor: Install a buffer plate or distribution guide below the feed inlet to evenly distribute the material across the entire screen width at a suitable speed and angle, eliminating localized impact points.

Second stage: Process optimization and auxiliary measures (operational assurance)

-Pretreatment control: Before the screening process, add or strengthen pretreatment steps such as drying, dispersion, and static removal to control the moisture content, agglomeration, and static electricity level of the material entering the screen.

-Activate auxiliary devices: Appropriately configure and activate systems such as hot air drying, forced-air penetration, or airflow sweeping to reduce the risk of clogging from a process perspective.

Phase Three: Establishing a Proactive Maintenance System (Long-Term Defense)

- Systematized Screen Cleaning System Inspection:

Bouncing Ball Screens: Check their freedom of movement and wear monthly; replace immediately if wear exceeds 1/3.

Ultrasonic Screens: Check power indicator lights and output intensity daily; clean transducer connection surfaces regularly.

- Implementing a Preventative Maintenance Plan:

Daily Inspection: Operators check screens for obvious looseness, damage, and blockage every shift.

Periodic Tightening: After a period of equipment operation (e.g., 8-24 hours), stop the machine, inspect, and retighten the screens ("hot tightening").

Recording and Analysis: Record the service life and failure modes of each screen to provide data support for subsequent selection and process improvement.

By linking the four links of "correct selection—standard installation—process adaptation—proactive maintenance" into a closed-loop management system, abnormal screen wear and blockage can be significantly reduced, ensuring long-term, stable, and efficient operation of the screening equipment.

Clearly separated grains, intelligent screening -- Mirant Xinxiang Machinery Equipment Co., Ltd.