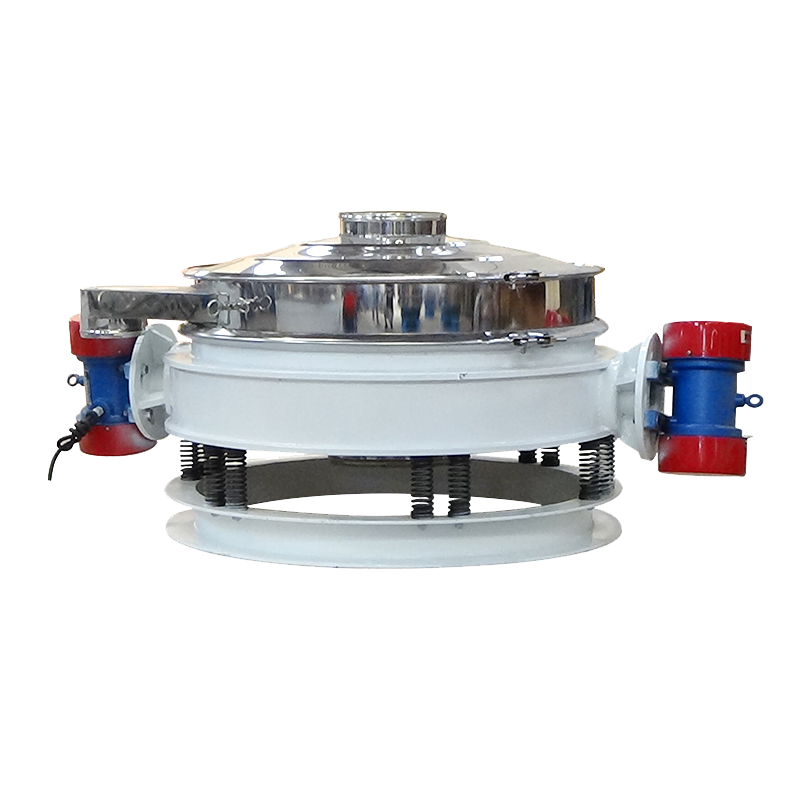

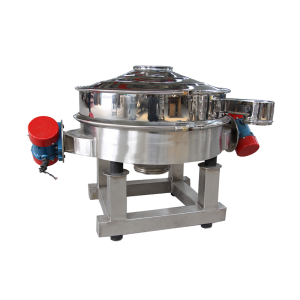

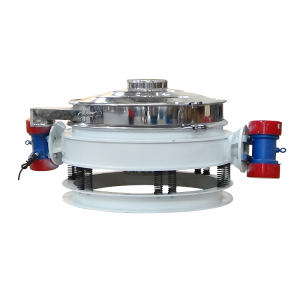

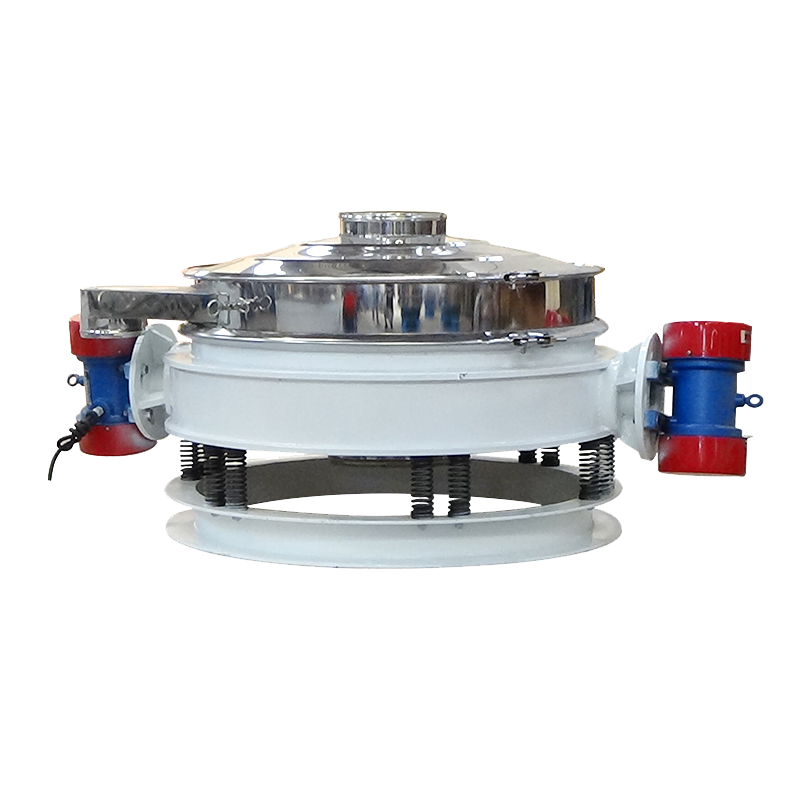

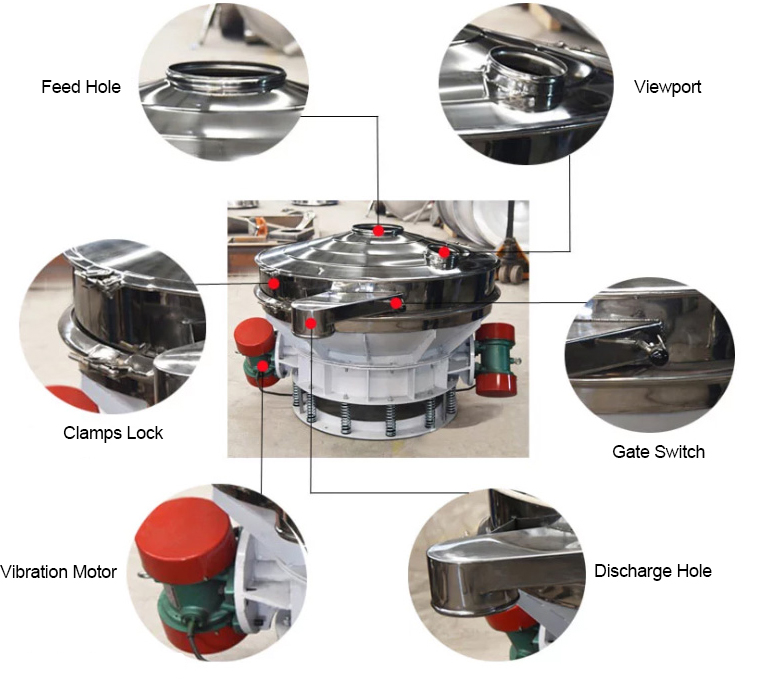

Mirant's Direct Discharge Screen is also called the direct discharge vibrating screen, which is divided into single vibration source and double vibration source.

The single vibration source mainly produces up and down vibration on the material, and does not have the automatic discharge function. The double vibration source can produce vortex motion on the screen surface and has the automatic discharge function.

The inline screen is mainly used for impurity removal and loosening of powder in the process flow of the powder production line.

Mirant's Direct Discharge Screen uses the phase angle of the two sets of eccentric blocks at the upper and lower ends of the vibration motor shaft and the angle of the angle between the two motors to convert the rotational motion of the vibration motor into multiple overlapping forces of horizontal, vertical, inclined and centrifugal action, and then transmits this force to the screen surface to achieve the purpose of screening. Changing the phase angle and weight of the upper and lower eccentric blocks can change the magnitude of the exciting force and the movement trajectory of the material.

1. Small size, easy to move.

2. Low energy consumption, high efficiency.

3. Easy to disassemble, assemble and clean inside and outside, in line with food-grade GMP standards.

4. Automated operation, 24-hour continuous production.

5. Ultra-low silent design.

6. Tightly sealed, no liquid leakage, no dust flying.

7. Can be used in single layer or multi-layer, multi-level screening at one time.

Material of the screen:

Stainless steel (mostly used in food, chemical and other industries, not easy to oxidize and rust)

Carbon steel (cheap, suitable for common materials)

Mirant's Direct Discharge Screen is widely used for screening, sorting and removing impurities of various powdery, granular and granular materials such as flour, starch, washing powder, material powder, additives, chemicals, metal powder, non-metallic minerals, etc. It can be selected from 600mm to 1800mm. The processing capacity can reach 350kg/150 seconds.

Model | A | B | C | D | E | F | G |

MLZP-600 | 600 | 150 | 380 | 560 | 325 | 110 | 80 |

MLZP-800 | 800 | 200 | 540 | 600 | 350 | 140 | 90 |

MLZP-1000 | 970 | 250 | 640 | 640 | 350 | 150 | 100 |

MLZP-1200 | 1170 | 250 | 700 | 700 | 400 | 160 | 120 |

MLZP-1500 | 1470 | 250 | 700 | 760 | 440 | 180 | 120 |

Model | Power(Kw) | Sieving Diameter(mm) | Dimension L*W*H(mm) |

MLZP-600 | 0.12 | 520 | 740*600*560 |

MLZP-800 | 0.18 | 720 | 1010*8/00*600 |

MLZP-1000 | 0.18 | 890 | 1200*970*640 |

MLZP-1200 | 0.25 | 1090 | 1430*1700*700 |

MLZP-1500 | 0.55 | 1390 | 1780*1470*760 |

This model of screen is usually used in flour industry and noodle making industry or related lines. It is the primary consideration for flour making stream line.

Q1: Why choose our machine?

A: Our company are specializing in all kinds of vibration screen more than 15 years. We have professional team to research and develop new and unique vibration.

Q2: What's raw material name? Bulk density (kg/m³)and water content (%)?

EM: Grain, Liquid, sand.......

Q3: How much mesh size do you want (mesh size of each layer)?

Single layer or Multi-lyayer is available. it's also can be customized by your requirements.

Q4: What's usually local power supply ______Voltage& ______Frequency in your city?

Various power voltage: 110V 200V 240V 380V 415V 450V 550V

Power Frequency: 50HZ 60HZ or Single phase electricity

Q5: What's material for machine do you need?

A Stainless steel 304

B Carbon steel Q235

C Touching parts SUS304

Q6: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of the most of our customers at home or abroad.

Q7: How do your after-sale service work if the product got damaged?

A: During the maintenance period, our general after-sale service is changing the damaged parts for the customer. Normally, we will provide on-site guidance.