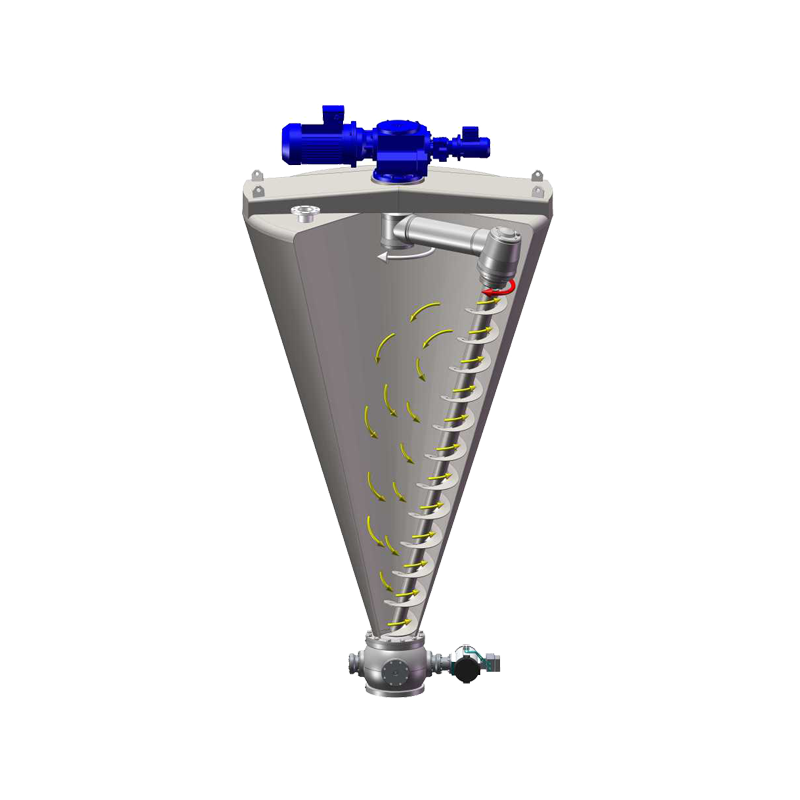

Mirant's Single Screw Conical Mixer is a new type of high-efficiency and high-precision particle mixing equipment. The central screw and the screw blades are connected through a reducer and run at the same speed. During operation, the central screw lifts the mixed material from the bottom to the top, and the high linear speed of the outer screw lifts the material from the bottom to the top along the conical barrel wall.

Under the action of centrifugal force, the material can be ejected along the tangential direction, generating strong convection shear and diffusion with the material, thereby achieving rapid mixing (the central screw can also be made into a reverse screw).

Mirant's Single Screw Conical Mixer is a new type of high-efficiency and high-precision particle mixing equipment. The central screw and the screw blades are connected through a reducer and run at the same speed. During operation, the central screw lifts the mixed material from the bottom to the top, and the high linear speed of the outer screw lifts the material from the bottom to the top along the conical barrel wall.

Under the action of centrifugal force, the material can be ejected along the tangential direction, generating strong convection shear and diffusion with the material, thereby achieving rapid mixing (the central screw can also be made into a reverse screw).

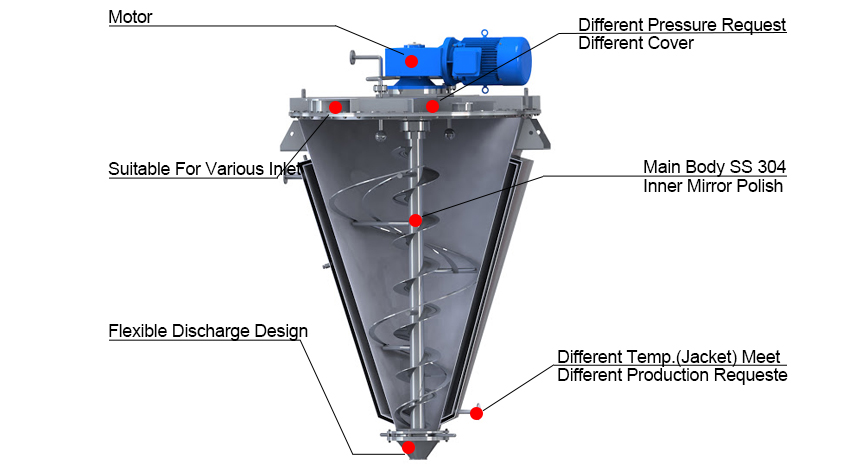

The structure of the Single Screw Conical Mixer consists of a barrel, a bracket, a feed port, a discharge valve, a transmission motor, a bracket shell, and an electrical control system. It is a high-efficiency mixing equipment that can be used for high-uniform mixing of powdered and granular materials in pharmaceutical, chemical, light industry, mechanical electronics, mining, national defense industry, agriculture and animal husbandry, scientific research and other enterprises and units. There is no centrifugal force in the mixing process, no gravity segregation and stratification, and accumulation. The components can be evenly mixed under the weight ratio of suspended beads. The charging coefficient can reach more than 40% and cannot exceed 60%. The mixing fluidity of this machine is good.

1. The spiral rotates along the wall, making the material move in a circular motion.

2. The screw rotates to make the material rise from the bottom of the cone along the screw.

3. The composite motion of the screw speed and revolution causes part of the material to be sucked into the screw, and at the same time, part of the material in the screw is quickly discharged under the action of centrifugal force.

4. The rising material falls under the action of its own gravity, and the four movements produce convection, shear and diffusion, thereby achieving rapid mixing.

5. A jacket (heating/cooling) and a sprayer can be installed outside the machine, which is suitable for powder and powder mixing reactions in the chemical, pharmaceutical, pesticide, dye, construction and other industries.

Mirant's Single Screw Conical Mixer is widely used in chemical, metallurgical, food, pharmaceutical, fertilizer, coating, pigment, dye, pesticide, rubber feed, additive, refractory, fine chemical, new material, electronic plastic, ceramic, mining, building materials and other industries.

Applicable materials:

Suitable for food, medicine, pesticide, zinc oxide, detergent, veterinary drug, compound fertilizer, feed, petroleum, metallurgical mining, building materials industry, coating, dye, pigment, additive, calcium carbonate, biology, ceramic, chemical, flavor, chicken essence, condiment, tea, grain, starch, plant fiber, milk powder, cocoa powder, flour, coffee, glucose and other materials.

Model | Volume(L) | Voltage(V) | Rotating Speed(r/min) | Size(mm) | Weight |

VH-20 | 20 | 220 | 0.25 | 500x250x490 | 45 |

VH-50 | 50 | 380 | 0.375 | 1150x500x750 | 95 |

VH-100 | 100 | 0.75 | 1800x650x1300 | 140 | |

VH-150 | 150 | 1.1 | 1900x700x1400 | 230 | |

VH-300 | 300 | 1.5 | 2320x800x1470 | 330 | |

VH-500 | 500 | 2.2 | 2520x900x1510 | 550 | |

VH-1000 | 1000 | 3 | 3040x1000x1765 | 1000 |

Q1: What's material you expect to grind?

Is it dry, what is the size of feed material?

Q2: How much capacity do you expect (kg/h)?

EM: 200kg/h

Q3: What's the materila of machine?

Usually we use Stainless steel 304, if you want Stainless steel 316, it's okay and please tell us.

Q4: What's usually power ______Voltage ______Frequency in your city?

For example, 380V 50Hz 3p; 440V 60Hz 3p; 220V.....etc.

(We only provide 3P, because our machine are all for industrial use, not for family)

Q5: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of the most of our customers at home or abroad.

Q6: How do your after-sale service work if the product got damaged?

A: During the maintenance period, our general after-sale service is changing the damaged parts for the customer. Normally, we will provide on-site guidance.