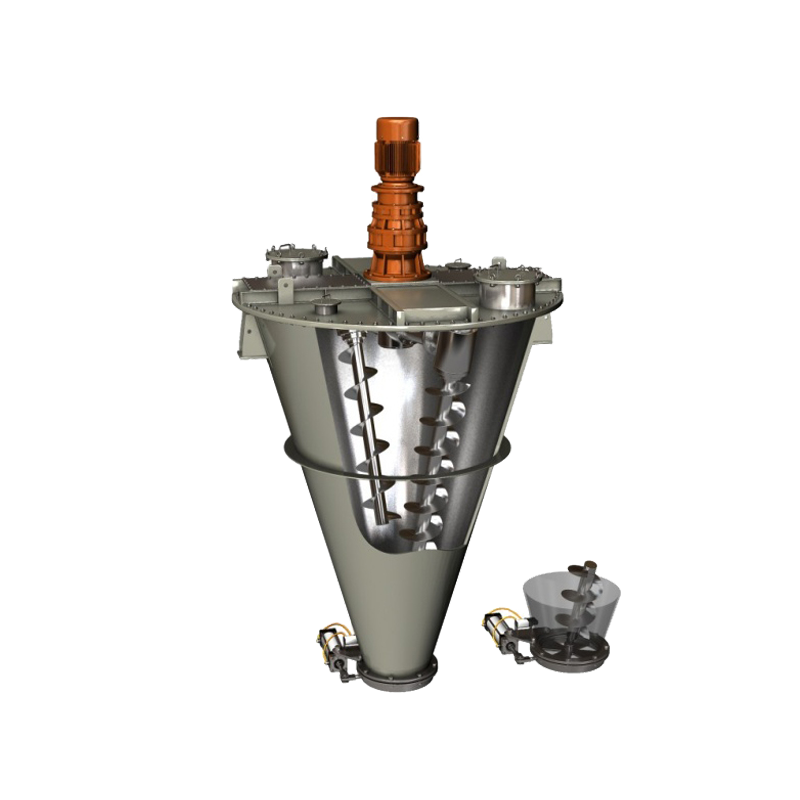

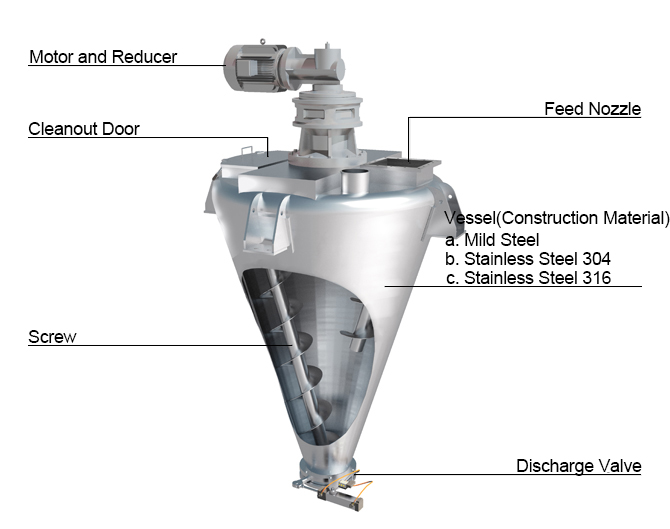

Mirant's Double Screw Conial Mixer is a new type of high-efficiency and high-precision particle mixing equipment. It is widely used in chemical, metallurgical, food, pharmaceutical, fertilizer, coating, pigment, dye, pesticide, rubber feed, additive, refractory, fine chemical, new material, electronic plastic, ceramic, mining, building materials and other industries.

It has a wide range of adaptability to mixed materials, suitable for powder, granular, slurry or viscous liquid, and can also be equipped with a spray system. It can be designed into vacuum state, pressure state, heating or cooling and other process conditions according to user requirements to meet the material mixing under various process conditions.

Mirant's Double Screw Conial Mixer rotates and revolves by an electric field and a cycloidal pin reducer. The two screws are used for asymmetrical mixing, which makes the material mixing range larger, the mixing more uniform, and the mixing speed faster. It is more suitable for mixing materials with different specific gravity and large mixing ratio. It has little wear and compression on granular materials, and does not cause overheating danger when mixing heat-sensitive materials. The mixed preparation is stable without stratification and segregation. It is airtight and dust-free, simple to operate, safe to run, easy to maintain, and has a long service life.

1. Due to the rotation and rotation of the twin screws, the particles move on the cone wall.

2. Due to the rotation of the spiral blades, the powder is discharged to the center of the cone for radial movement.

3. The powder flows upward from the bottom of the cone and is discharged to the surface around the outside of the screw for material mixing.

4. The powder flows downward due to the rotation of the screw of the twin screw conical mixer. Due to the combination of the rotation of the screw in the mixer, the flow forms of the powder include: convection, shear, diffusion and penetration.

5. Fully enclosed structure, no dust flying.

6. Gentle stirring, will not damage fragile materials.

7. Low energy consumption, more adaptable to chemical and physical reactions.

Mirant's Double Screw Conial Mixer is widely used in the mixing, reaction, drying and cooling of powders and powders, powders and liquids (solid-liquid) in chemical, metallurgical, food, pharmaceutical, fertilizer, coating, pigment, dye, pesticide, rubber feed, additive, refractory, fine chemical, new material, electronic plastic, ceramic, mining, building materials and other industries.

Model | Working capacity (m³) | Working capacity (kg) | Revolution/ rotation | Power (kw) | Weight (kg) | D | H |

DSH-0.3 | 0.18 | 200 | 3.5/120 | 3 | 500 | 950 | 2060 |

DSH-0.5 | 0.3 | 300 | 3.5/120 | 3 | 600 | 1150 | 2350 |

DSH-1 | 0.6 | 650 | 3/78 | 4 | 1200 | 1580 | 2840 |

DSH-2 | 1.2 | 1200 | 3/78 | 5.5 | 1500 | 1950 | 3500 |

DSH-3 | 1.8 | 1800 | 3/78 | 7.5 | 2300 | 2170 | 3760 |

DSH-4 | 2.4 | 2500 | 1.8/65 | 11 | 2520 | 2280 | 4360 |

DSH-6 | 3.6 | 3600 | 1.6/65 | 15 | 3700 | 2560 | 4800 |

DSH-10 | 6 | 6000 | 1/65 | 18.5 | 3980 | 3000 | 5900 |

DSH-15 | 9 | 9000 | 1/65 | 22 | 4500 | 3450 | 6680 |

DSH-20 | 12 | 12000 | 1/44 | 37 | 5500 | 3770 | 6700 |

DSH-30 | 18 | 18000 | 1/44 | 45 | 6800 | 4100 | 7500 |

Q1: What's material you expect to grind?

Is it dry, what is the size of feed material?

Q2: How much capacity do you expect (kg/h)?

EM: 200kg/h

Q3: What's the materila of machine?

Usually we use Stainless steel 304, if you want Stainless steel 316, it's okay and please tell us.

Q4: What's usually power ______Voltage ______Frequency in your city?

For example, 380V 50Hz 3p; 440V 60Hz 3p; 220V.....etc.

(We only provide 3P, because our machine are all for industrial use, not for family)

Q5: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of the most of our customers at home or abroad.

Q6: How do your after-sale service work if the product got damaged?

A: During the maintenance period, our general after-sale service is changing the damaged parts for the customer. Normally, we will provide on-site guidance.