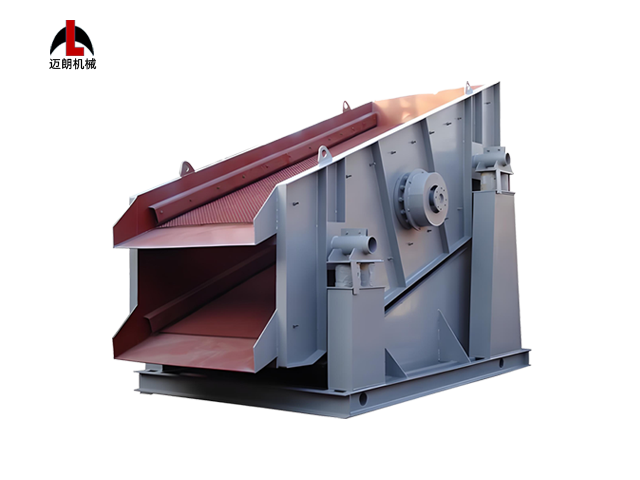

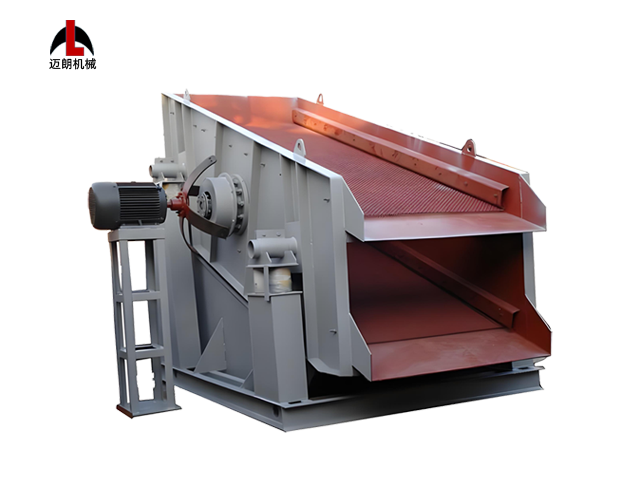

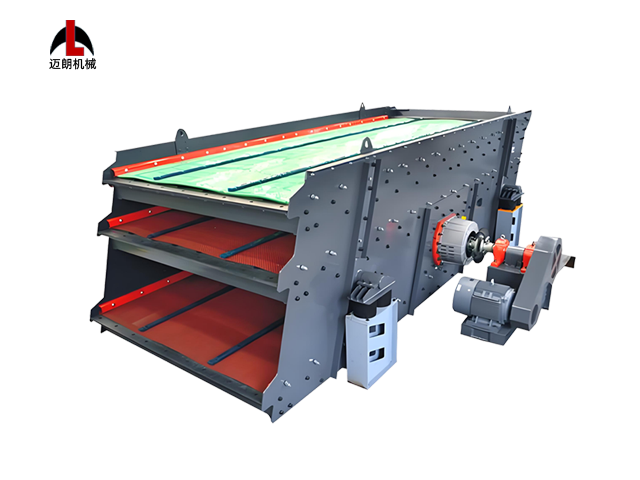

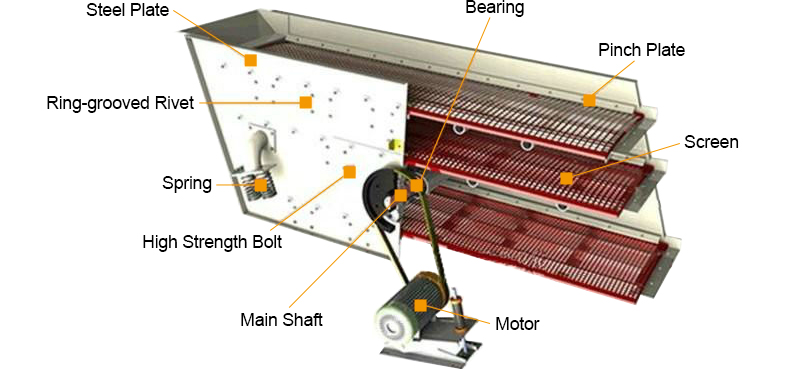

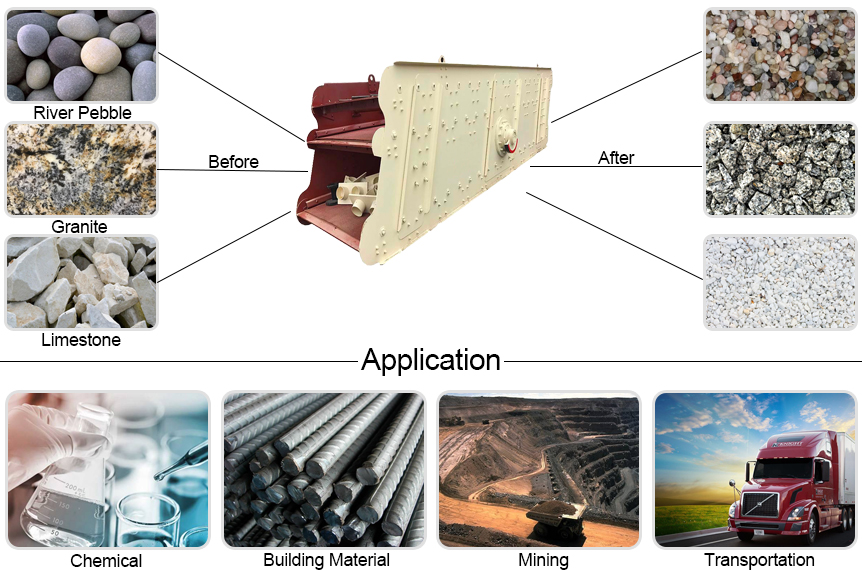

Mirant's Circle Vibrating Screen, not only aggrandizes the single vibration power of vibrator but also can charge the stimulating-power stochastically, suitable for modularization design and use. Sieving structure going to be simple, which is suitable to improve producing craftwork level and assembling precision of equipment. Adopting cross axle universal joint or rubber coupling etc. flexible joint, stable operation with the characteristics of high screening efficiency, large processes volume disposal quality, long period using and whole machine using life.

Mirant's Circle Vibrating Screen has been sucessfully used for the product classification in mine, building material, transportation, energy and chemistry.

Model | Layer Number | Screen mesh Area (m³) | Screen mesh Dimesion (mm) | Supplied Material Granularity (mm) | Processing Volume (t/h) | Inclination (o°) | Rotation speed (r/min) | Double Amplitude (mm) | Matching motor | Reference weight (KG) | |

Model | Power (kw) | ||||||||||

YK1230 | 1 | 4.3 | 60-80 | ≤50 | 75-245 | 15-30 | 980 | 6-12 | Y160M-6 | 7.5 | 5050 |

2YK1230 | 2 | 4.3 | 75-245 | Y160L-6 | 11 | 5415 | |||||

YK1530 | 1 | 4.5 | 80-255 | Y180L-6 | 15 | 4765 | |||||

2YK1530 | 2 | 4.5 | 80-255 | Y180L-6 | 15 | 5100 | |||||

YK1536 | 1 | 5.4 | 95-310 | Y180L-6 | 15 | 5735 | |||||

2YK1536 | 2 | 5.4 | 95-310 | Y180L-6 | 18.5 | 5620 | |||||

YK1542 | 1 | 6.3 | 110-360 | Y180L-6 | 15 | 6215 | |||||

2YK1542 | 2 | 6.3 | 110-360 | Y200L1-6 | 18.5 | 6030 | |||||

YK1548 | 1 | 7.2 | 125-410 | Y180L-6 | 18.5 | 6445 | |||||

2YK1548 | 2 | 7.2 | 125-410 | Y200L1-6 | 18.5 | 5310 | |||||

YK1836 | 1 | 6.5 | 115-370 | Y200L1-6 | 18.5 | 6060 | |||||

2YK1836 | 2 | 6.5 | 115-370 | Y200L1-6 | 18.5 | 5940 | |||||

YK1842 | 1 | 7.6 | 135-430 | Y200L1-6 | 18.5 | 6560 | |||||

2YK1842 | 2 | 7.6 | 135-430 | Y200L1-6 | 18.5 | 6410 | |||||

YK1848 | 1 | 8.6 | 150-490 | Y200L1-6 | 18.5 | 6755 | |||||

2YK1848 | 2 | 8.6 | 150-490 | Y200L1-6 | 18.5 | 5470 | |||||

YK2148 | 1 | 10 | 10-100 | ≤200 | 175-570 | 8-14 | Y225M-8 | 22 | 10640 | ||

2YK2148 | 2 | 10 | 175-570 | Y225M-8 | 30 | 10640 | |||||

YK2160 | 1 | 12.6 | 220-715 | Y225M-8 | 22 | 10120 | |||||

2YK2160 | 2 | 12.6 | 220-715 | Y225M-8 | 30 | 11320 | |||||

YK2448 | 1 | 11.5 | 200-650 | 760 | Y225M-8 | 30 | 9940 | ||||

YK2460 | 1 | 14.4 | 250-810 | Y225M-8 | 30 | 12310 | |||||

2YK2460 | 2 | 14.4 | 250-810 | Y280S-8 | 37 | 13640 | |||||

YK3060 | 1 | 18 | 300-960 | Y250M-8 | 30 | 14500 | |||||

Q1: How to solve the problem of blocking mesh?

All of most vibrating screen adopts bouncing ball and PU ring below every deck to cleaning screen surface,except the ultrasonic vibrating screen adopts ultrasonic cleaning systerm.

Q2: How to seal the machine?

Between two decks, it's adopt silica gel ring to seal. Then the clamp would lock two decks tightly with the extended copper nut.

Q3: Could this machine be refitted and designed technology to suit our production line?

Yes. All of machines in our factory could be customized by client's specific requirement such as the height from outlet to ground, the inlet shape&outlet shape, and the gate design on first deck. and the gate design on first deck.

Q4: How can i get the spare parts for machine?

The matched spares, such as seal ring, bouncing ball, screen plate, clamp screws and nut could be ordered one set or more as customer's need.