This solution aims to provide clients with a "one-stop" service, encompassing project planning, engineering design, equipment integration, installation and commissioning, final production target achievement, and technical training. It offers a turnkey EPC (Engineering, Procurement, and Construction) solution for screening production lines, centered on high efficiency, intelligence, and reliability. This completely resolves the pain points clients face when constructing complex screening systems, such as multi-interface coordination difficulties, technical integration challenges, and high risks related to schedule and cost control.

I. Core Advantages and Value

1. Single Responsible Entity: As the EPC contractor, we bear overall responsibility for the quality, safety, schedule, and cost of the entire project. Clients only need to contact us, ensuring efficient communication and clear responsibilities.

2. Full-Process Professional Integration: Based on a deep understanding of the process and rich project experience, we provide customized design, optimize process layout, and precisely select a complete set of equipment from feeding, screening, conveying, dust removal to intelligent control, ensuring optimal system synergy.

3. Controllable Schedule and Cost: Through standardized project management processes and a supply chain system, we achieve deep integration and efficient coordination between design, procurement, and construction, minimizing the construction cycle and controlling the total project investment.

4. Emphasis on both technological advancement and reliability: Core screening equipment (such as tension screens, high-frequency screens, and probability screens) utilizes high-performance products from leading brands in the industry or developed in-house, combined with an advanced intelligent control system (PLC/SCADA) to achieve stable operation, accurate screening, and fault early warning.

5. Turnkey delivery: The project is ready for production upon completion. We are responsible for all commissioning and performance testing (ensuring key indicators such as throughput, screening efficiency, and product particle size), and provide comprehensive operation and maintenance training.

II. System Solution Composition

1. Process Design and Optimization: Based on material characteristics (particle size, moisture content, viscosity, specific gravity, etc.), throughput, product specifications, and site conditions, process flow simulation and design are conducted to determine the optimal number of screening layers, screen configuration, and process layout.

2. Core Equipment Package:

Feeding System: Stable and uniform feeding equipment (e.g., vibrating feeder).

Screening System: Targeted main screening equipment (circular vibrating screen, linear screen, tension screen, etc.), multi-layer grading screens and matching screens, anti-clogging devices.

Material Conveying System: Belt conveyors, screw conveyors, or lifting equipment for oversize and undersize materials.

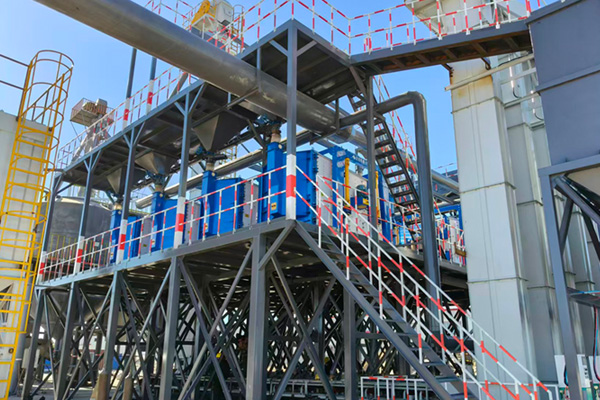

Environmental Protection and Auxiliary Systems: High-efficiency pulse bag dust collector system, steel structure platform, maintenance facilities, safety protection.

Electrical and Automation Control System: Integrated electrical control cabinet, PLC control system, human-machine interface (HMI), online monitoring of key parameters (flow rate, current, temperature, vibration), remote operation and maintenance interface.

3. Project Implementation and Management:

Detailed Design: Construction drawings, 3D modeling, interference checks.

Procurement and Supervision: Factory supervision of key equipment to ensure quality.

Construction and Installation: Professional installation team, standardized construction.

Commissioning and Training: Single-unit commissioning, integrated commissioning, material-loaded trial operation, performance evaluation, compilation of operation and maintenance manuals.

III. Application Areas

Widely used in material classification, dewatering, demediuming, and impurity removal processes in industries such as mining (metal and non-metallic minerals), coal, building materials (sand and gravel aggregates), metallurgy, chemicals, and grain processing.

Mirant Xinxiang Machinery Equipment Co., Ltd.'s EPC turnkey solutions, through a systematic engineering approach, deliver not just a simple collection of equipment, but a technologically advanced, economical, stable, and reliable modern screening production system, helping customers quickly achieve high-quality production capacity and enhance their market competitiveness.